Recently, I asked the Girl Camper Facebook group: what is your number one question or concern regarding using propane in your RV? There was a common theme that included fear of a fire, what exactly the detectors are doing, and a general uncertainty of how the system operates. Let’s see if we can address some of those concerns while talking about propane system maintenance.

First, propane is not only inexpensive, it is also one of the safest fuel sources we use in our RVs. And, ongoing inspection and maintenance of the propane system are imperative for your safety and to protect the value of your RV. Here is a list of simple maintenance items to help give you some peace of mind when using your propane appliances.

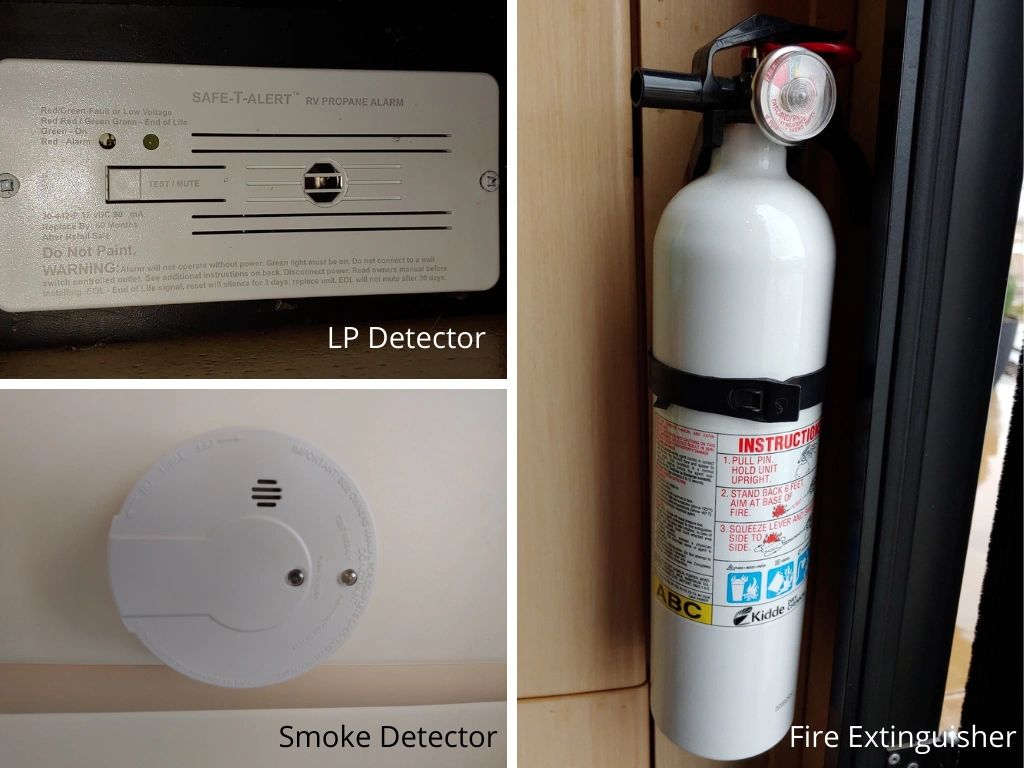

Test detectors regularly and inspect your fire extinguisher

Your LP detector might be a stand alone or be a combo with your carbon monoxide detector and should be no more than 6” from the floor of the RV. Also, make a mental note that this detector runs on 12V power from your house battery. Your smoke detector is usually on the ceiling near the door and often runs on a 9V battery. The push button test is sufficient for both of these. If either are not operative or functioning properly, check the power sources and/or replace.

If the LP detector is beeping, it means there is LP present, the battery power is too low, or the detector is nearing the end of its life. Never disconnect the detector or cut the wires. Your fire extinguisher should be rated for your RV size and located near the main entry door. The gauge should be in the fully charged status.

Monitor the dates on all of your detectors

The manufacture dates for both smoke and LP/carbon monoxide detectors are on the back of the item. It is recommended to replace CO/LP detectors at the 5-7 year mark and smoke detectors at the 5-10 year mark.

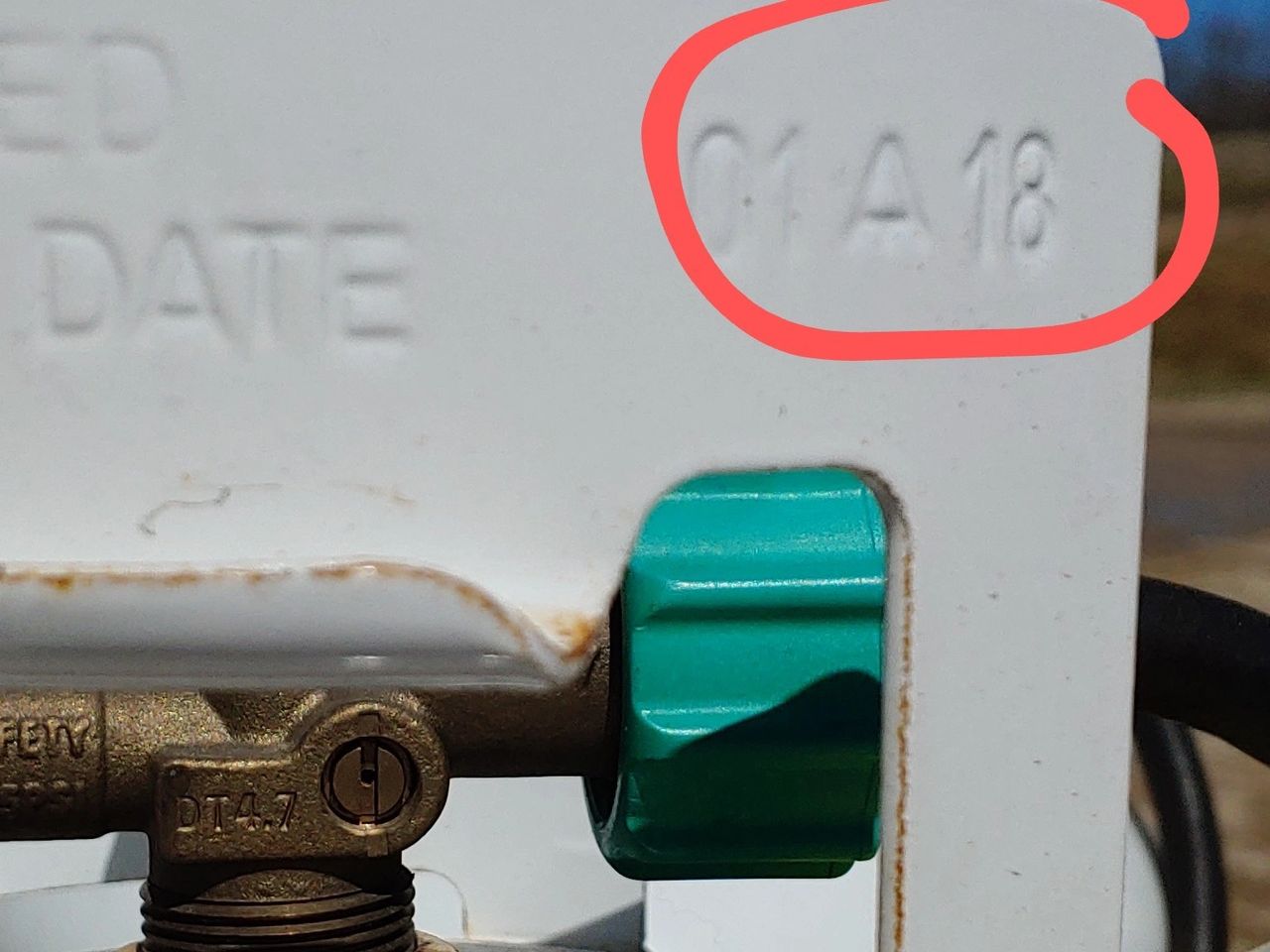

Know your DOT dates on your cylinders

Your travel trailer or 5th wheel propane cylinders have a manufacture date stamped into the collar. Ten years after this date, they must be re-certified by an authorized propane technician. If you drive a motorized rig, you are familiar with the ASME tank—these tanks do not expire, however, they could fail. Inspect both cylinders and tanks periodically for excessive wear and tear, dents, and scrapes.

Monitor the age of your regulator and have it replaced every 5-7 years.

Get a professional leak test done annually

A qualified technician or certified inspector like me can do this for you in about 15-20 minutes.

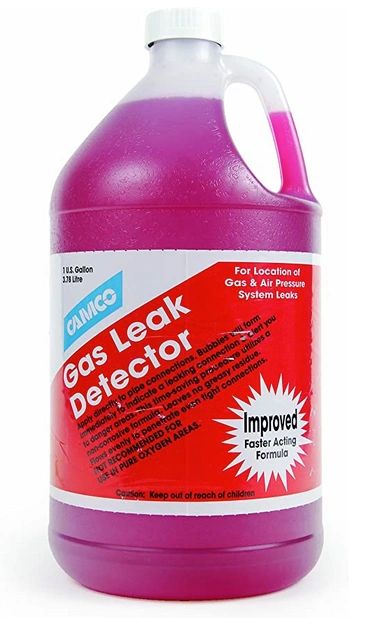

You can also periodically check for leaks. Using the product specifically designed for propane leak testing, spray or swab the solution on any LP gas fittings and connections. If bubbles are detected, turn off the LP system and do not continue use until it is inspected and repaired by a qualified technician.

Keep your house battery charged

Remember, the LP and/or CO detectors are operating off this 12V system.

I hope this information is helpful and you can hit the road with some peace of mind after performing some of these simple checks!